Photo Report

Japan International Welding Show 2024, the biggest event in Japan’s welding sector, held at Intex Osaka,

dramatically

showcasing new technologies and products

The photo shows Japan International Welding Show 2024, the biggest event in Japan’s welding sector (organized by the

Japan Welding Engineering Society and Sanpo Publications Incorporated). The show, held in Osaka for the first time

in

eight years, was very well attended every day throughout the event, attracting many people who were fascinated to

see

the latest technology developments.

Environmentally-conscious Welding Materials Proposed by Many Exhibitors

Amid the global trend for carbon neutrality, manufacturers of welding materials exhibited welding materials for the

special materials used to construct fuel tanks and pipelines for hydrogen, industrial ammonia, and LNG, as well as

low-spatter, low-fume welding materials, which help to address the shortage of welders. Furthermore, welding wires

specifically designed for welding robots and automated equipment for improving production quality and efficiency

were

exhibited.

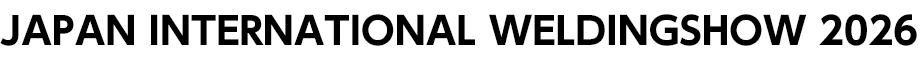

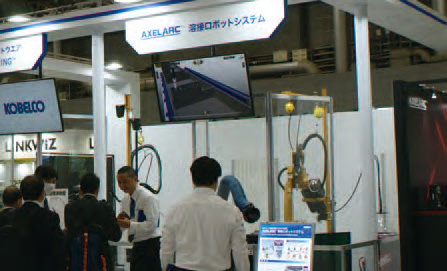

The wire feed control process AXELARC combined with a special wire reduces spattering. (Kobe Steel)

The extremely low-hydrogen FCW “CF Wire” reduces preheating. (Nippon Steel Welding & Engineering)

Primarily, welding materials for hydrogen, industrial ammonia, and LNG, which play a leading role in

decarbonizing, were

on display. (Nippon Welding Rod)

Stainless steel, nickel steel, WAAM-system AM wires, and various other welding materials were on display.

(Taseto)

Various brazing materials were on display along with a demonstration of a robot-based automatic machine.

(Nies)

Standard Machines Integrating the Characteristics of Various Welding Machines

A super standard machine integrating the characteristics of a thyristor, inverter, and digital functions

attracted much

attention. (Daihen)

A sample TIG welding machine equipped with a welding concierge to simplify the setting of welding conditions

was on

display. (Panasonic)

A backpack, battery-powered welding machine had a great impact on visitors. (Denyo)

The TIG Dynamic Wire, which automatically feeds TIG filler wires from the side of the torch, was on display.

(Fronius)

A low-temperature spot forge welding machine incorporating spot welding was on display among others. The

photo shows a

plastic-metal joining machine. (Dengensha Toa)

A table spot welding machine equipped with high-speed welding technology was demonstrated. (Koyo Giken)

Master-level welding technology solutions were offered. (Taiyo Nippon Sanso)

Laser-related Exhibitors Up 50%. Hand-held Fiber Laser Machines Increased Rapidly.

Many companies exhibited hand-held laser welding machines.

A new low-priced model that narrowed the gap with Chinese products (Aim)

A 4 kW blue laser oscillator was on display. (Laserline)

A hand-held blue laser was a hot topic. (North Hillz Welding Industry)

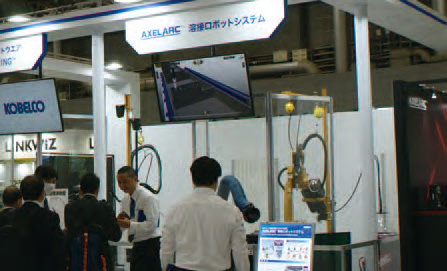

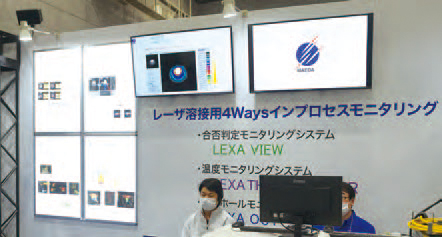

A process monitoring system capable of confirming welding workmanship (Maeda Kogyo)

A variable-beam fiber laser machine highly effective for processing copper and aluminum was on display. (IPG

Photonics)

Showcasing Various Cutting Applications

Fiber laser cutting machines were the mainstream. The photo illustrates a fiber laser groove cutting machine

equipped

with a 20 kW-class oscillator from Nissan Tanaka.

Publicity information focused on a dual-beam-controlled fiber laser cutting machine. (Koike Sanso Kogyo)

Cutting using a hydrogen fuel gas was demonstrated. (Iwatani Corporation)

An underwater fiber laser processing machine was on display. (Komatsu Industries)

High-speed laser cutting by a high-precision robot was demonstrated. (Fanuc)

A plasma cutting robot developed by Daihen was demonstrated. (Is-tail)

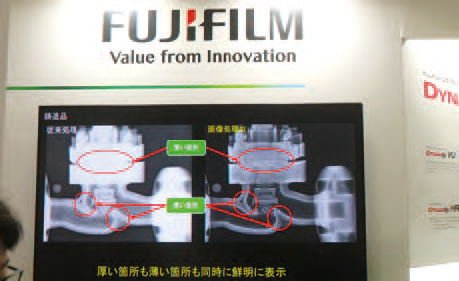

Digital Radiographic Testing (RT) Attracted Attention.

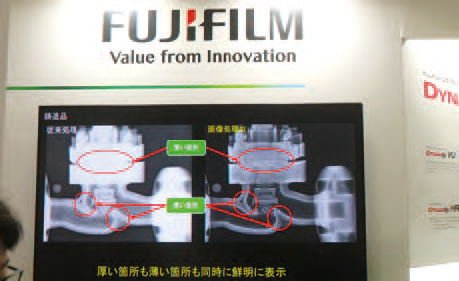

Digital X-ray equipment gathered attention. (Fujifilm)

A measuring instrument and digital eddy-current inspection machine used to evaluate the quenching depth of

steel after

high-frequency or carburizing quenching (Denshijiki Industry)

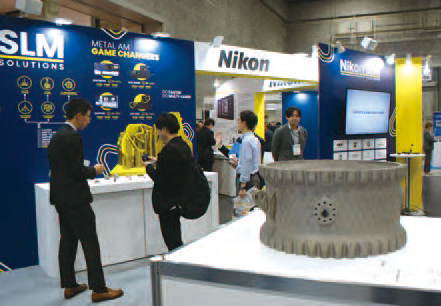

Additive Manufacturing (AM) Technology with Broader Applications

A fuel tank manufactured in the Manufacturing Technology Project for Rocket Liquid Fuel Tanks Using AM

(Japan Aerospace

Exploration Agency)

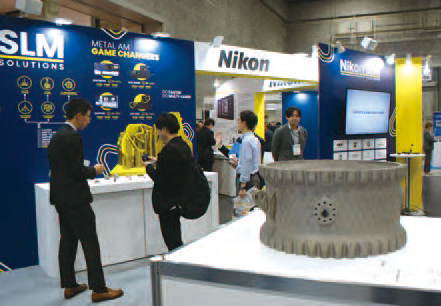

Nikon exhibited an object created by a DED 3D printer.

DMG Mori proposed the DED system.

The wire feed control process AXELARC combined with a special wire reduces spattering. (Kobe Steel)

The wire feed control process AXELARC combined with a special wire reduces spattering. (Kobe Steel)

The extremely low-hydrogen FCW “CF Wire” reduces preheating. (Nippon Steel Welding & Engineering)

The extremely low-hydrogen FCW “CF Wire” reduces preheating. (Nippon Steel Welding & Engineering)

Primarily, welding materials for hydrogen, industrial ammonia, and LNG, which play a leading role in

decarbonizing, were

on display. (Nippon Welding Rod)

Primarily, welding materials for hydrogen, industrial ammonia, and LNG, which play a leading role in

decarbonizing, were

on display. (Nippon Welding Rod)

Stainless steel, nickel steel, WAAM-system AM wires, and various other welding materials were on display.

(Taseto)

Stainless steel, nickel steel, WAAM-system AM wires, and various other welding materials were on display.

(Taseto)

Various brazing materials were on display along with a demonstration of a robot-based automatic machine.

(Nies)

Various brazing materials were on display along with a demonstration of a robot-based automatic machine.

(Nies)

A super standard machine integrating the characteristics of a thyristor, inverter, and digital functions

attracted much

attention. (Daihen)

A super standard machine integrating the characteristics of a thyristor, inverter, and digital functions

attracted much

attention. (Daihen)

A sample TIG welding machine equipped with a welding concierge to simplify the setting of welding conditions

was on

display. (Panasonic)

A sample TIG welding machine equipped with a welding concierge to simplify the setting of welding conditions

was on

display. (Panasonic)

A backpack, battery-powered welding machine had a great impact on visitors. (Denyo)

A backpack, battery-powered welding machine had a great impact on visitors. (Denyo)

The TIG Dynamic Wire, which automatically feeds TIG filler wires from the side of the torch, was on display.

(Fronius)

The TIG Dynamic Wire, which automatically feeds TIG filler wires from the side of the torch, was on display.

(Fronius)

A low-temperature spot forge welding machine incorporating spot welding was on display among others. The

photo shows a

plastic-metal joining machine. (Dengensha Toa)

A low-temperature spot forge welding machine incorporating spot welding was on display among others. The

photo shows a

plastic-metal joining machine. (Dengensha Toa)

A table spot welding machine equipped with high-speed welding technology was demonstrated. (Koyo Giken)

A table spot welding machine equipped with high-speed welding technology was demonstrated. (Koyo Giken)

Master-level welding technology solutions were offered. (Taiyo Nippon Sanso)

Master-level welding technology solutions were offered. (Taiyo Nippon Sanso)

Many companies exhibited hand-held laser welding machines.

Many companies exhibited hand-held laser welding machines.

A new low-priced model that narrowed the gap with Chinese products (Aim)

A new low-priced model that narrowed the gap with Chinese products (Aim)

A 4 kW blue laser oscillator was on display. (Laserline)

A 4 kW blue laser oscillator was on display. (Laserline)

A hand-held blue laser was a hot topic. (North Hillz Welding Industry)

A hand-held blue laser was a hot topic. (North Hillz Welding Industry)

A process monitoring system capable of confirming welding workmanship (Maeda Kogyo)

A process monitoring system capable of confirming welding workmanship (Maeda Kogyo)

A variable-beam fiber laser machine highly effective for processing copper and aluminum was on display. (IPG

Photonics)

A variable-beam fiber laser machine highly effective for processing copper and aluminum was on display. (IPG

Photonics)

Fiber laser cutting machines were the mainstream. The photo illustrates a fiber laser groove cutting machine

equipped

with a 20 kW-class oscillator from Nissan Tanaka.

Fiber laser cutting machines were the mainstream. The photo illustrates a fiber laser groove cutting machine

equipped

with a 20 kW-class oscillator from Nissan Tanaka.

Publicity information focused on a dual-beam-controlled fiber laser cutting machine. (Koike Sanso Kogyo)

Publicity information focused on a dual-beam-controlled fiber laser cutting machine. (Koike Sanso Kogyo)

Cutting using a hydrogen fuel gas was demonstrated. (Iwatani Corporation)

Cutting using a hydrogen fuel gas was demonstrated. (Iwatani Corporation)

An underwater fiber laser processing machine was on display. (Komatsu Industries)

An underwater fiber laser processing machine was on display. (Komatsu Industries)

High-speed laser cutting by a high-precision robot was demonstrated. (Fanuc)

High-speed laser cutting by a high-precision robot was demonstrated. (Fanuc)

A plasma cutting robot developed by Daihen was demonstrated. (Is-tail)

A plasma cutting robot developed by Daihen was demonstrated. (Is-tail)

Digital X-ray equipment gathered attention. (Fujifilm)

Digital X-ray equipment gathered attention. (Fujifilm)

A measuring instrument and digital eddy-current inspection machine used to evaluate the quenching depth of

steel after

high-frequency or carburizing quenching (Denshijiki Industry)

A measuring instrument and digital eddy-current inspection machine used to evaluate the quenching depth of

steel after

high-frequency or carburizing quenching (Denshijiki Industry)

A fuel tank manufactured in the Manufacturing Technology Project for Rocket Liquid Fuel Tanks Using AM

(Japan Aerospace

Exploration Agency)

A fuel tank manufactured in the Manufacturing Technology Project for Rocket Liquid Fuel Tanks Using AM

(Japan Aerospace

Exploration Agency)

Nikon exhibited an object created by a DED 3D printer.

Nikon exhibited an object created by a DED 3D printer.

DMG Mori proposed the DED system.

DMG Mori proposed the DED system.